Pressure Gage a Reads 1.5 Kpa (Gage).the Fluids Are at 20ã”â¨. Determine the

Pressure Gauges are pressure level measuring instruments. Pressure and Temperature are two very important parameters for all chemical industries. So, pressure measurement is of utmost importance. In that location are various pressure measuring instruments available to perform this task. Force per unit area measurement basically means the analysis of the fluid forces that are imparted on a surface. Accuracy of pressure level measuring instruments are very important for proper operational control. In this article, we volition explore various pressure measuring devices or pressure gauges used beyond industries.

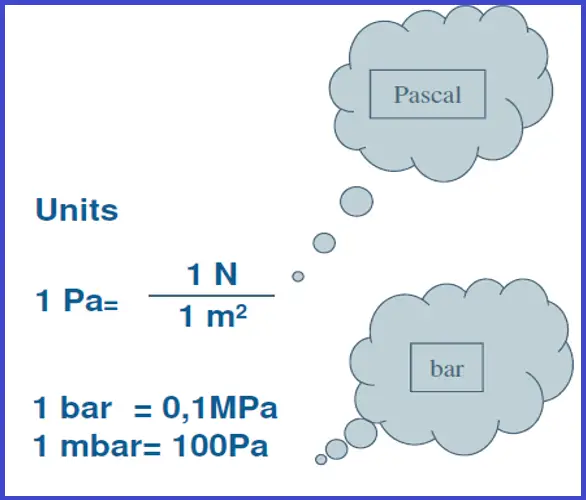

What is Pressure?

- Pressure level (P) is divers as Force (F) per Unit Area (A).

- The pressure is the action of ane force against some other force.

- The pressure is the strength practical to or distributed over a surface.

- P = F/A F: Forcefulness A: Area

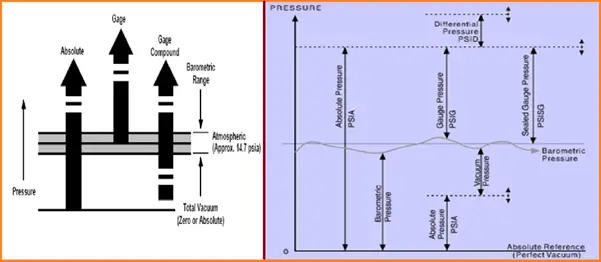

Accented pressure

- Measured higher up total vacuum or zero absolute.

- Nil accented represents a full lack of pressure.

- Range: 0-ane Kg/cm^2 (a)/ 0-1 Bar (a)/ 0-760 mm Hg (a)

Atmospheric pressure level: The pressure exerted by the earth's atmosphere.

Barometric pressure: Aforementioned as Atmospheric pressure.

Vacuum Pressure level: Pressure beneath atmospheric.

Differential pressure: Information technology is the deviation in pressure between ii points of measurements. In a sense, Accented Pressure could be considered as a differential pressure with a total vacuum or nothing absolute as the reference.

Judge/Gage force per unit area: The pressure level higher up atmospheric is approximate pressure level. Represents a positive difference betwixt measured and existing atmospheric force per unit area. For example – Blood pressure.

Pressure Measurement

The measurement of pressure is considered the bones process variable for measurement of:-

- Menses (departure of 2 pressures).

- Level (Head or backpressure).

- Temperature (Fluid pressure level in a filled thermal system).

The Pressure Measurement Systems consist of two bones parts:-

- A primary element, which is in contact, straight or indirectly, with the pressure medium and interacts with pressure level changes.

- A secondary element, which translates this interaction into appropriate values for indicating, recording, and/or controlling.

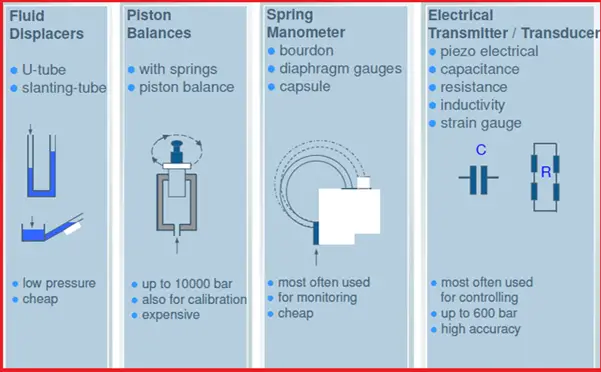

Classification of Force per unit area Measuring Instruments or Pressure Gauges

Pressure measuring devices can be classified on the footing of :

A: Pressure ranges:- Vacuum gage, Draft cuff, Low range, compound gage, Medium range, high range, etc..

B: Pattern principle involved in their performance:

- Mechanical movement of the sensing element – east.g. Bourdon gages, Diaphragm gages

- Electronic Sensors: e.g. Strain gages, Capacitive, Potentiometric, Resonant wire, Piezoelectric, Magnetic, Optical, etc.

C: On the basis of their application:

- Local pressure indication,

- Remote pressure indication,

- Corrosive service

- Pulsating service

- Differential pressure measurement

Methods of Pressure level Measurement

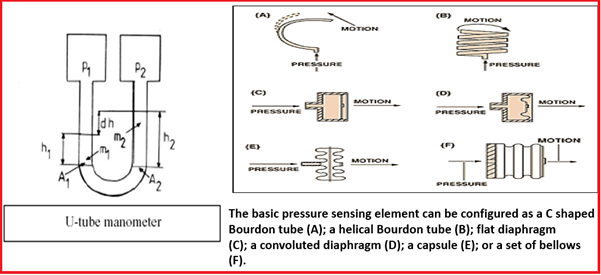

Bones Measurement – U Tube Manometer

A manometer is one of the oldest pressure level measuring instruments and widely used even in recent times. Their operation is simple and provides accurate results. As the name suggests it is a "U" shaped tube fabricated of drinking glass and partially filled with liquid.

The principle of the manometer is given equally P= Superlative*DENSITY Where "P" is Pounds /sq. Inch; "Height" in Inch " DENSITY" in pounds /Cu. Inch

Advantages of Manometer

- Fluids uncomplicated & time-proven

- High accuracy & sensitivity

- Broad range of filling

Disadvantages of Manometer

- No over-range protection

- Large & beefy

- Measured fluids must be compatible with the manometer fluids

- Need for leveling

Pressure level Sensing Elements

Pressure Sensing Elements are basically mechanical elements like plates, shells, and tubes. On the application of force per unit area, these elements deflect which is then converted into physical motility. They are a very of import role of pressure level measuring devices.

- The main types of sensing elements are Bourdon tubes, diaphragms, capsules, and bellows.

- All the above devices, except diaphragms, provide a adequately large deportation. Mechanical gauges use that displacement which is further used by electric sensors that require a significant movement.

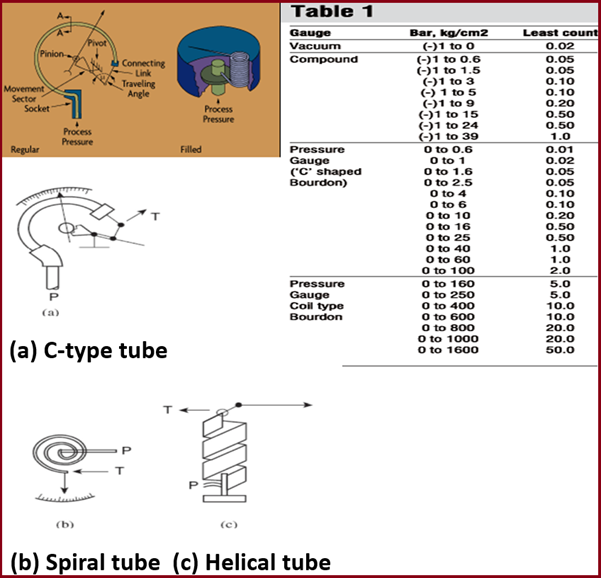

Bourdon Tube Pressure Gauges

The pressure measuring device, Bourdon tube is the well-nigh common. They measure out medium to high pressures. Bourdon tube is basically a curved tube with a circular, coiled, or spiral shape.

- It is the twisted tube whose cantankerous-sectional isn't circular.

- Bourdon tubes types are c-blazon, helical type and spiral blazon.

- They should be filled with oil to limit the damage caused by vibration.

- Range: (-)1 to 1600 Kg/cm^2

Advantages of Bourdon Tube

- Depression price & simple structure

- Wide rangeability

- Good accurateness

- Adaptable to transducer designs

Disadvantages of Bourdon Tube

- Low spring gradient below 50psig

- Subject to Hysteresis

- Susceptible to shock & vibration

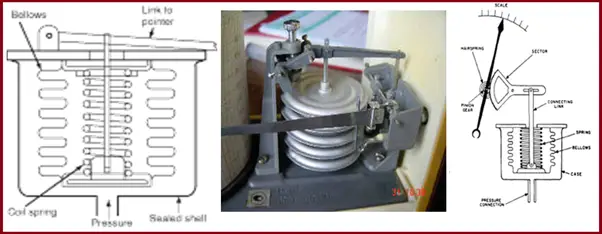

Bellows type Pressure Gauge

Bellows are also used as a pressure measuring instrument. Their main features are

- Fabricated of Statuary, S.South., BeCu, Monel, etc..

- The movement is proportional to a number of convolutions sensitivity is proportional to size.

- In full general, a bellows can detect a slightly lower force per unit area than a diaphragm.

- The range is from 0-5 mmHg to 0-2000 psi

- Accuracy in the range of one% bridge

- It is a series of a circular parts so formed or joined that they can be expanded axially by pressure. A wide range of spring is employed to limit the travel of bellows.

- The measurement is limited from .5 to 70 psi.

- It is greatly used as receiving elements for pneumatic recorders, indicators & controllers & also as a differential unit of measurement of flow measurement.

Advantages of Bellows Pressure Approximate

- High force delivered

- Moderate cost

- Good in the low to moderate pressure level gauge

Disadvantages of Bellows Pressure Judge

- Need ambient temperature pressure bounty

- Require spring for authentic characteristics

- Limited availability

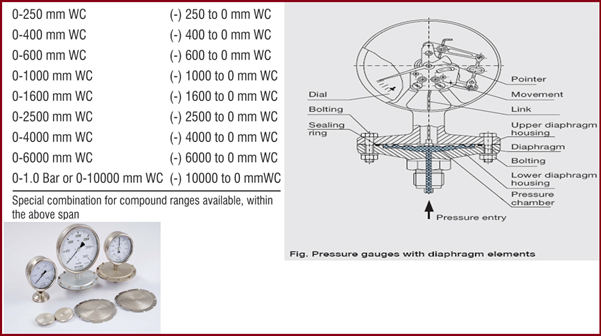

Diaphragm Force per unit area Gauge

The diaphragm can exist used to mensurate the pressure of both liquids and gases. One circular diaphragm is clamped between a pair of flanges to constitute the pressure level measuring element.

- The deflection of a flexible membrane is used for pressure level measurement.

- For known pressures, the deflection is repeatable. Hence, scale is possible.

- The pressure difference betwixt its two faces dictates the deformation of a thin diaphragm.

- The reference face up can be open up to the temper to measure gauge pressure, open to a second port to measure differential pressure, or can be sealed confronting a vacuum or other fixed reference pressure to measure absolute pressure. Mechanical, optical, or capacitive techniques are used to measure the deformation. Ceramic and metallic diaphragms are used.

- Range: (-) 10000 to (+) 10000 mm-WC

Advantages of Diaphragm pressure estimate

- Small size & moderate cost

- Linearity

- Adaptability to slurry services & absolute & diff. press.

- Loftier over range characteristics

Disadvantages of Diaphragm pressure level gauge

- Limited to low pressure level

- Difficult to repair

- Less vibration & shock resistance

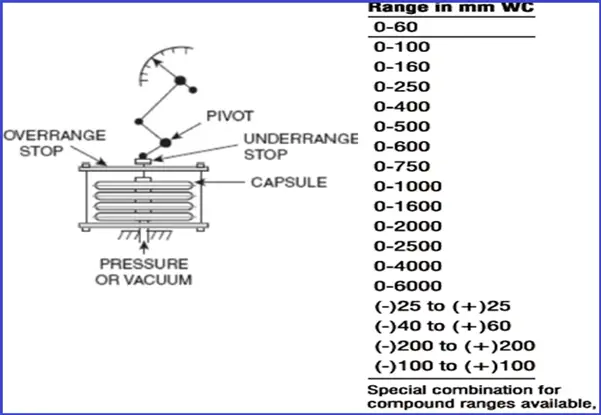

Capsule Pressure Gauge

Capsules every bit pressure measuring devices are used normally for low pressure applications.

- A sheathing is formed by joining the peripheries of ii diaphragms through soldering or welding.

- Used in some absolute pressure gages.

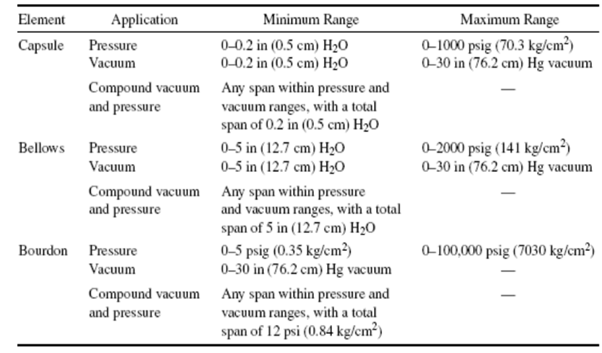

Range of Elastic-Element Pressure level Gages

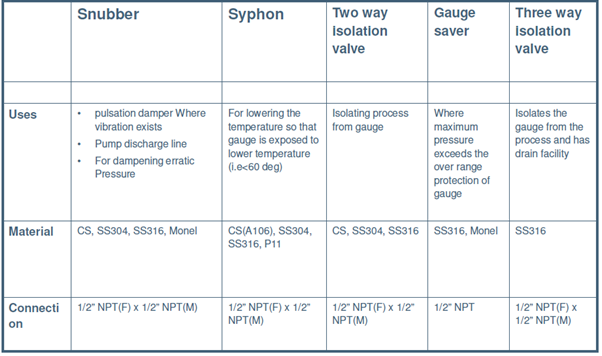

Pressure Measuring Accessories

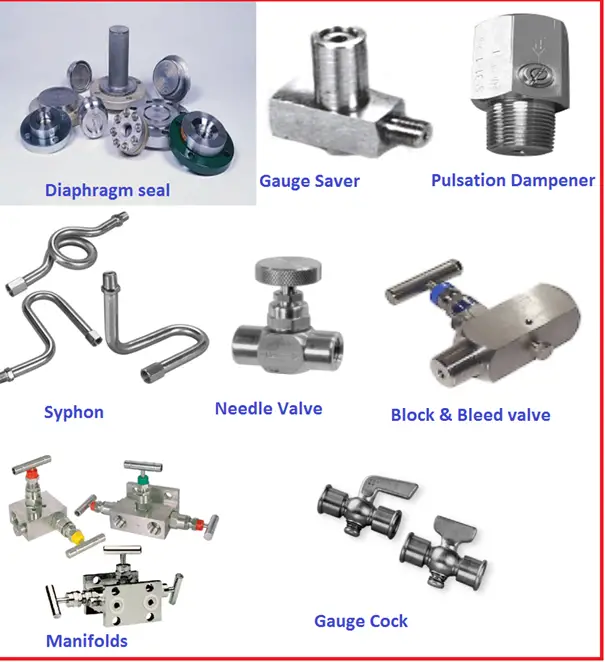

Diaphragm seals: These are designed to isolate the sensing chemical element of force per unit area gauges from procedure fluids.

Guess Saver: Approximate Savers also known every bit overpressure protectors are applicable where pressures exceed the maximum pressure rating of the force per unit area gauge.

Pulsation dampener: Dampeners considerably reduce the pulsations and make the gauge reading easier and also improves the life of the gauge.

Siphon: This connectedness between the pressure gauge & process in applications, where high temperatures similar steam, vapors or fluids are present. Information technology acts as a cooling curl and protects the gauge from loftier temperatures and too helps in dissipating estrus.

Precautions: When kickoff installed the siphon should be filled with h2o or whatever other suitable separate liquid.

- U Type – For Horizontal pressure tapping

- Q Type – For vertical pressure borer

Needle valve: The large round handle offers maximum ease and precise control to throttle the pressure to the gauge.

Block & Drain Valve: Equipment Isolation with automatic pressure level bleed for rubber

Manifolds

- These are fluid distribution devices.

- These are used in conjunction with pressure level gauges, differential pressure level gauges & differential pressure transmitters.

- They combine musical instrument isolation & equalizing in ane block.

- The manifolds are available in 2way, 3 way & 5-fashion types with remote & direct mounting styles

Gauge cack: It is used in conjunction with the siphon as an isolation valve. It is not recommended for pressure level over 100 psi.

Few more than resources for yous.

Understanding Pressure level and Temperature in the context of Pressure level Vessel Design

Pressure Tests of Piping systems-Hydrotest Vs Pneumatic Test

Temperature Measurement by Filled Thermal Systems

FUNDAMENTALS OF TEMPERATURE: An article

Few Points for High Temperature and High-Pressure Piping

Source: https://whatispiping.com/pressure-pressure-measuring-instruments-1/

Postar um comentário for "Pressure Gage a Reads 1.5 Kpa (Gage).the Fluids Are at 20ã”â¨. Determine the"